Introduction

These

guidelines describe requirements regarding resistance measurement of joints,

and comprise measurement method and limit values for replacement of joints. The

purpose is to ensure that measurements are performed in the same way, that

measurement errors are minimized and that joints in bad condition are replaced

Scope

These

guidelines concern resistance measurement of joints. They cover how to perform

measurements, requirements on the measurement equipment and limit values for

replacement for joints

Definitions

Technical

terms and definitions used in this document:

Device

for joining two lengths of conductor to provide mechanical and electrical

continuity. Conductor here relates to phase conductor or shield wire. A joint

in a line span (mid-span joint or dead-end joint) has also, in addition to

electrical connection, the function of maintaining the full mechanical strength

of the conductor.

Compression joint

A

joint assembled by compression

Detonation compressed joint

A

compression joint compressed by detonation of an explosive charge wound around

the sleeve of the joint

Hydraulic compressed joint

Compression

joint compressed by a hydraulic tool

Screw joint

A

joint consisting of factory compressed sleeves on each conductor end, which are

joined by a screw sleeve

Bolted connector

A

joint or a clamp where contact is obtained by a bolted connection

Where

Rj

= is the resistance of the joint,

Rc

= is the resistance of the conductor per meter, read from datasheet,

Lj

= is the length of the joint in meters.

The

use of K – value has the advantage

of independence of conductor type and joint length

Temperature dependency of resistance

Specified

resistance values for conductors refer to 20O C. the same reference

temperature is applicable for the limit values specified in this document. The

following formula gives the resistance at other temperatures, if the resistance

at 20O C is known

Where

R20

= the resistance at 20O C

Rθ

= the resistance at temperature θ

θ

= the actual temperature

α= 0.004 for aluminum

(temperature coefficient)

A

temperature difference of 10 degrees corresponds to 4% resistance difference

for aluminum

Performing resistance measurement

General procedure

Concerning

full tension compression joins

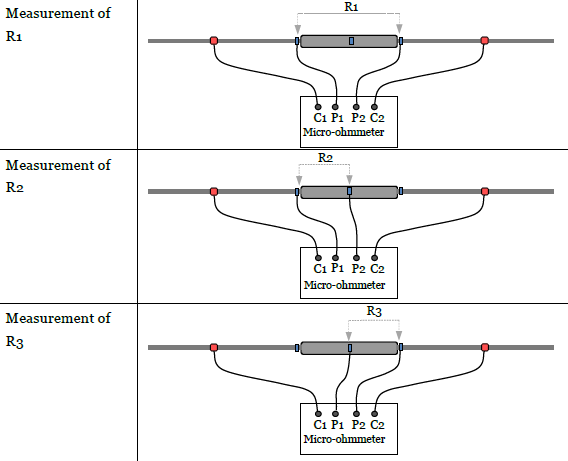

Three

resistance values shall be measured: the whole joint R1, and the two

halves R2 and R3 is towards higher tower number

Figure 1 Joint Resistances

Apply

the clamps according to Figure 2; with the current clamps furthest out and the

measurement clamps on each side of the joint, and a measurement clamp on the

mid of the joint. The current clamps shall be placed at least 0.5 meter from

the joint. The measurement clamps on each side of the joint shall be placed 5mm

from the joint, but must not be in contact with the joint.

Figure: 2 Application of clamps, with a

photo as an example

Connect

the micro ohmmeter according to Figure: 3 from measurement of R1, R2

and R3 respectively

Figure:

3 Connection for measurement of R1, R2 and R3

Measurement

procedure for old joint or new joint on old conductor:

*Measurement

. Measure

the resistance R1

. Move

one measurement lead to the middle of the joint and measure R2

. Measure

R3 in the same way

. Note

the measured values,

*Loosen

the two measurement clamps on the conductor adjacent to the joint and rotate

them about 1/3 revolution

*Repeat

the measurement and note the values

*Loosen

the measurement clamps again and rotate another 1/3 revolution

*Repeat

the measurement and note the values

All measurement values shall be reported. The average

of the three measurements shall be compared with the applicable limit value.

Measurement

procedure for new joint or new conductor:

*As

above, but the measurement need not be repeated

Measurement

of special joint

Basic measurement principles are according to section

4.1

Compressed

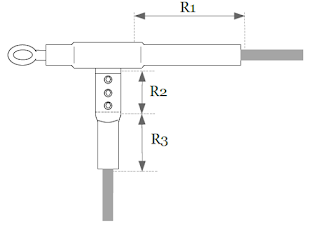

dead end connector

For compressed dead end connector the resistance R1,

R2 and R3, according to Figure: 4, shall be measured. For

R1 and R3 the measurement procedure according to section

4.1 is applicable, with three repetitions. For R2 the measurement

need not be repeated.

Figure: 4 compressed dead end connector resistances

Screw

Joint

For screw joint the

resistance R1, R2, R3 and R4,

according to Figure: 5, shall be measured. For R1, R2 and

R4 the measurement procedure according to section 4.1 shall be

applied, with three repetitions. For R3 the measurement need not be

repeated

Figure:5 Screw Joint Resistance

Bolted

connectors

For parallel groove clamps and T-clamps the resistances

according to Figure 6 shall be measured. The measurements need not be repeated.

Figure 6 Bolted connectors resistances

Risks

for measurement errors

Insufficient

contact between conductor strands

The largest risk for errors in resistance measured on

old joints is due to old conductors often having bad contact between the

strands. This makes the measurement current unevenly distributed and may cause

large measurement errors, especially for joints that have an increased

resistance. The deviations can be both positive and negative.

Obtaining measurement values with good precision and

repeatability would require clamps that contact the whole circumference of the

conductor and at least 2 meters distance to the current clamps. Since this is

difficult to achieve in practice, we have chosen here a compromise, based on

three repeated measurements and moving the measurement clamps in between. The

resulting average value of the three measurements gives a reduction of the

error. In addition, the difference between the three measurements gives an

indication of the degree of this problem for each single case.

For new joints, on new conductors, this is normally not

a problem, and therefore repeated measurements are not required in this case.

Measurement of conductor resistance on old conductors

is also very uncertain, for the same reason. Therefore conductor resistance

should be taken from datasheets

Influence

of temperature

The temperature dependency of resistance is described

in section 3.

Regarding measurements on old joints, the temperature

effect is often negligible in comparison with other error sources. For new

joints the temperature may however significantly affect the comparison with the

required limit values.

The temperature can be accounted for by adjusting the

limit value to the prevailing ambient temperature. Possible solar heating may

be neglected.

A special case applies for measurement of newly

detonation-compressed joints, with remaining heat from the detonation. In this

case the surface temperature of the joint needs to be measured simultaneously

with the resistance measurement.

The use of instruments with built-in automatic

temperature compensation involves additional risks, e.g. due to erroneously set

values of temperature coefficient or reference temperature. The requirements

here applied for reporting of measurement values mean that such automatic

temperature compensation need normally not be used.

Joint

resistance

The following requirements apply to resistance at the

measurement occasion. These requirements shall be applied if nothing else has

been agreed on.

Requirements

for old mid-span joints

For old phase conductor mid-span joints, the limit

values in section 6.6 apply.

Joints that show higher measured resistance than the

limit value shall be replaced. This applies also if only one of the parts

exceeds the limit value.

For a screw joint, if the problem is in the screw

sleeve, this shall be corrected, after which a new measurement is made.

Requirements

for new mid-span joints

New

joint on new conductor

For new joint on new conductor reference is made to TR

05-07E, with the following additions.

The limit value shall be adjusted to the temperature of

the joint; normally the ambient temperature can be used.

For measurements of newly detonation-compressed joints,

with remaining heat from the detonation, the surface temperature of the joint

must be measured by a surface temperature probe simultaneously with the

resistance measurement.

New

joint on old conductor

For new joint on old conductor the resistance may not

exceed the type test value by more than 10 % + 2 μΩ. The same additions as

under 6.2.1 apply.

Requirements

for bolted connectors

New

bolted connector on new conductor

For new bolted connector on new conductor reference is

made to TR 05-15E.

New

bolted connector on old conductor

For new bolted connector on old conductor the

resistance may not exceed 0.6 times the corresponding conductor length (k =

0.6).

Old

bolted connectors

If measurement of an old bolted connector shows higher

resistance than the corresponding conductor length (k=1.0), the connector shall

be opened; brushed by a wire brush, coated by contact paste, brushed again and

reassembled, after which a new measurement is made.

Requirements

for dead-end joints

For dead-end joints, the limit values in section 6.6

apply for the compressions joints on line span conductor and on jumper

conductor. For the bolted jumper connection, the requirement according to

section 6.3 applies.

The dead-end joint shall be replaced if any of the

compression joints exceed the limit value. If the bolted jumper connection

exceeds the limit value, then it shall be corrected (see 6.3.3) after which a

new measurement is made.

Requirements

for joints on shield wires

For new joints on shield wires, the requirements

according to section 6.2 apply.

An old joint in a shield wire shall be replaced if the

measured resistance exceeds the limit value in section 6.7.

Limit

values for old joints on phase conductors

Table 1 lists limit values in the form of k-values as a

function of the highest continuous operating temperature of the line. Joints

constitute a higher risk, and age faster, at higher current load. Therefore the

limit values are stricter for lines operated at higher temperatures.

The limit values are for the reference temperature 20OC,

however, adjustment for the temperature at measurement need not be made for

measurements on old joints.

Table 1 Limit values for old joints, represented by

k-value.

Highest continuous

conductor temperature (OC)

|

K- Value

|

50

|

1.5

|

60

|

1.4

|

65

|

1.3

|

70

|

1.2

|

80

|

1.1

|

85

|

1.0

|

Limit values in micro-ohms can be obtained as: 𝑅= Rc×k×L

Where Rc = conductor resistance in μ/m (see Table 2)

k = k-value

L = the length over which the resistance is measured.

Table 2 contains listed values in micro-ohm/meter, i.e.

Rc×k, for joints on common conductors.

Table 2 Limit values in micro-ohm/meter joints on

common conductors, for different values of highest continuous conductor

temperature.

Conductor type, area

|

Conductor

resistance1 (µΩ/m)

|

Limit value for

joint, in resistance per meter (μΩ/m), at highest continuous conductor

temperature:

|

|||||

500C

|

600C

|

650C

|

700C

|

800C

|

850C

|

||

Dove, 329

|

102

|

153

|

143

|

133

|

122

|

112

|

102

|

Condor, 454

|

72

|

108

|

101

|

94

|

86

|

79

|

72

|

Curlew, 593

|

55

|

83

|

77

|

72

|

66

|

61

|

55

|

Morkulla,593

|

51

|

77

|

71

|

66

|

61

|

56

|

51

|

Martin, 772

|

42

|

63

|

59

|

55

|

50

|

46

|

42

|

Ripa, 774

|

39

|

59

|

55

|

51

|

47

|

43

|

39

|

Orre, 910

|

33

|

50

|

46

|

43

|

40

|

36

|

33

|

454AI59

|

65

|

98

|

91

|

85

|

78

|

72

|

65

|

774AI59

|

38

|

57

|

53

|

49

|

46

|

42

|

38

|

910AI59

|

33

|

50

|

46

|

43

|

40

|

36

|

33

|

593AIMgSi-B

|

52

|

78

|

73

|

68

|

62

|

57

|

52

|

774AIMgSi-B

|

40

|

60

|

56

|

52

|

48

|

44

|

40

|

910AiMgSi-B

|

34

|

51

|

48

|

44

|

41

|

37

|

34

|

1) DC resistance at 20 °C, from datasheet, rounded to

integer values.

Example of how to use Table 2:

For a joint on a Curlew-conductor, with measured length

0.81 m, and a highest continuous operating temperature of 50 OC, the

limit value is obtained as follows.

The distance between the measurement clamps, when

measuring R1, is 1 cm longer than the joint. This gives L = 0.82 m.

Table 2 gives the limit value 83 μΩ/m. This multiplied by L gives 0.82×83 = 68

μΩ. For R2 and R3, the length is L/2 and the limit value

half the value applied for R1. The limit values to be applied are:

R1: 68 μΩ

R2, R3: 34 μΩ.

Limit

values for old joints on shield wires

The following limit value, in the form of k-value,

applies for old joints on shield wires:

k= 2.0

Table 3 contains listed values in micro-ohms/meter. The

table is used as described in section 6.6.

Table 3 Limit values in micro-ohms/meter for joints on

shield wires, for common types of shield wires.

Conductor type,

area

|

Conductor

resistance 1 (μΩ/m)

|

Limit value for

joint, in resistance per meter(μΩ/m)

|

Dotterel, 142

|

323

|

646

|

Ibis, 234

|

143

|

286

|

Atle, 241

|

190

|

380

|

Ymer, 319

|

115

|

230

|

1) DC-resistance at 20 °C, from datasheet, rounded to

integer values.

Documentation

Required

content

Measurement protocols shall be delivered in

Excel-format and contain at least the following information:

* Measurement

performed by: Company and person

*Date

when the measurement was performed

*Identification

of measurement instrument: type and id-number

*Identification

of measurement object:

· Line

· Line designation

· Conductor type

· Highest continuous operating temperature

· Joint type (hydraulic compressed, detonation compressed, screw joint etc.)

· Length of the joint

* Ambient

temperature

*Limit

value applied

*Identification

of joint individual: Span no, Conductor no

*All

measurement values. Values larger than 10 µΩ may be rounded to integers

*Average

values of repeated measurements

*Commentary

field: any action taken, visual observations etc.

Example

of measurement protocol

Figure 7 gives an example of measurement protocol for

old joints.

Regarding measurement

protocol for new installations, reference is made to TR05-07E for joint and TR

05-15E for bolted connector

No comments:

Post a Comment